ABSTRACT

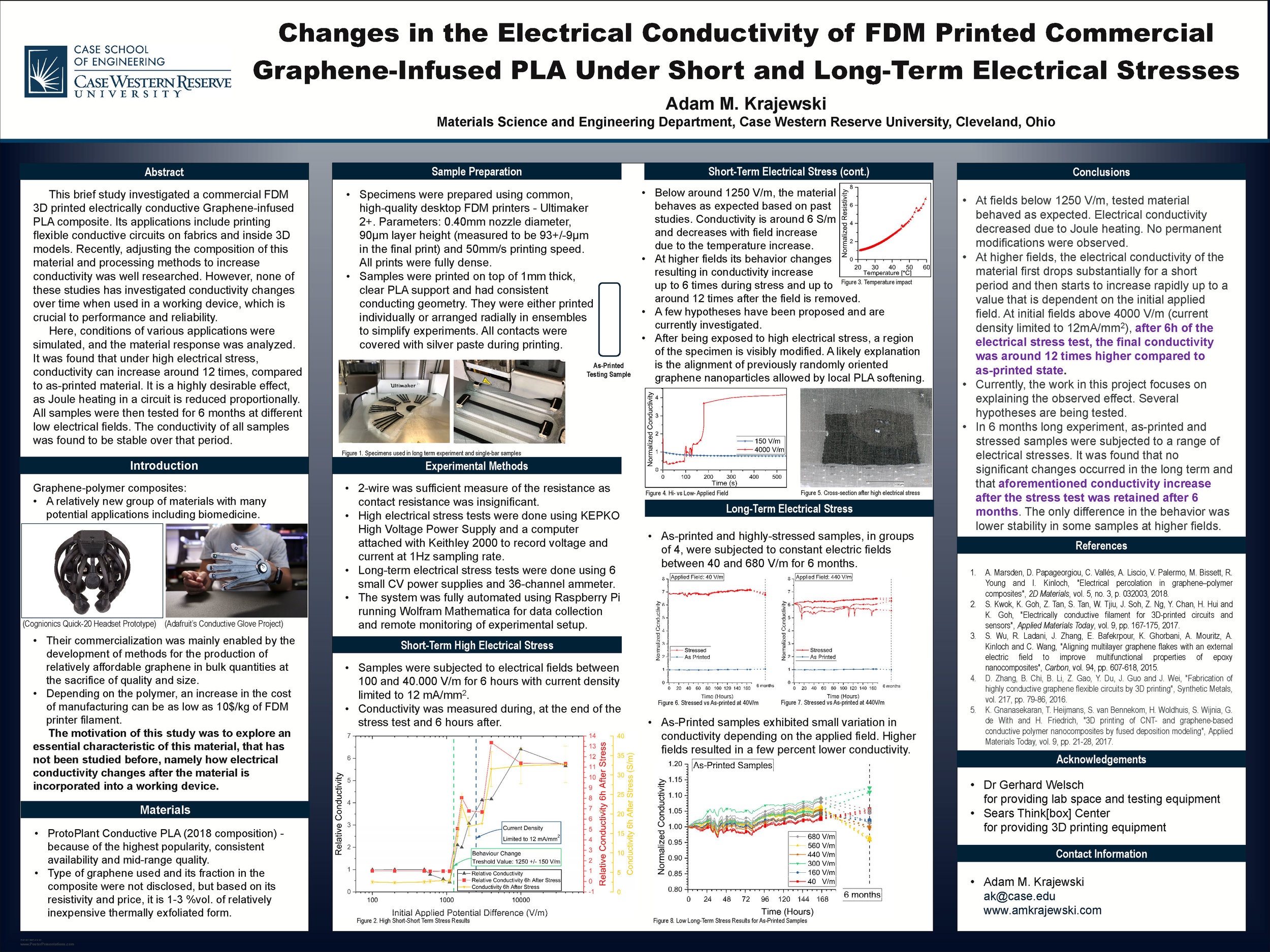

This brief study investigated a commercial FDM 3D printed electrically conductive Graphene-infused PLA composite. Its applications include printing flexible conductive circuits on fabrics and inside 3D models. Recently, adjusting the composition of this material and processing methods to increase conductivity was well researched. However, none of these studies has investigated conductivity changes over time when used in a working device, which is crucial to performance and reliability.

Here, conditions of various applications were simulated, and the material response was analyzed. It was found that under high electrical stress, conductivity can increase around 12 times, compared to as-printed material. It is a highly desirable effect, as Joule heating in a circuit is reduced proportionally. All samples were then tested for 6 months at different low electrical fields. The conductivity of all samples was found to be stable over that period.